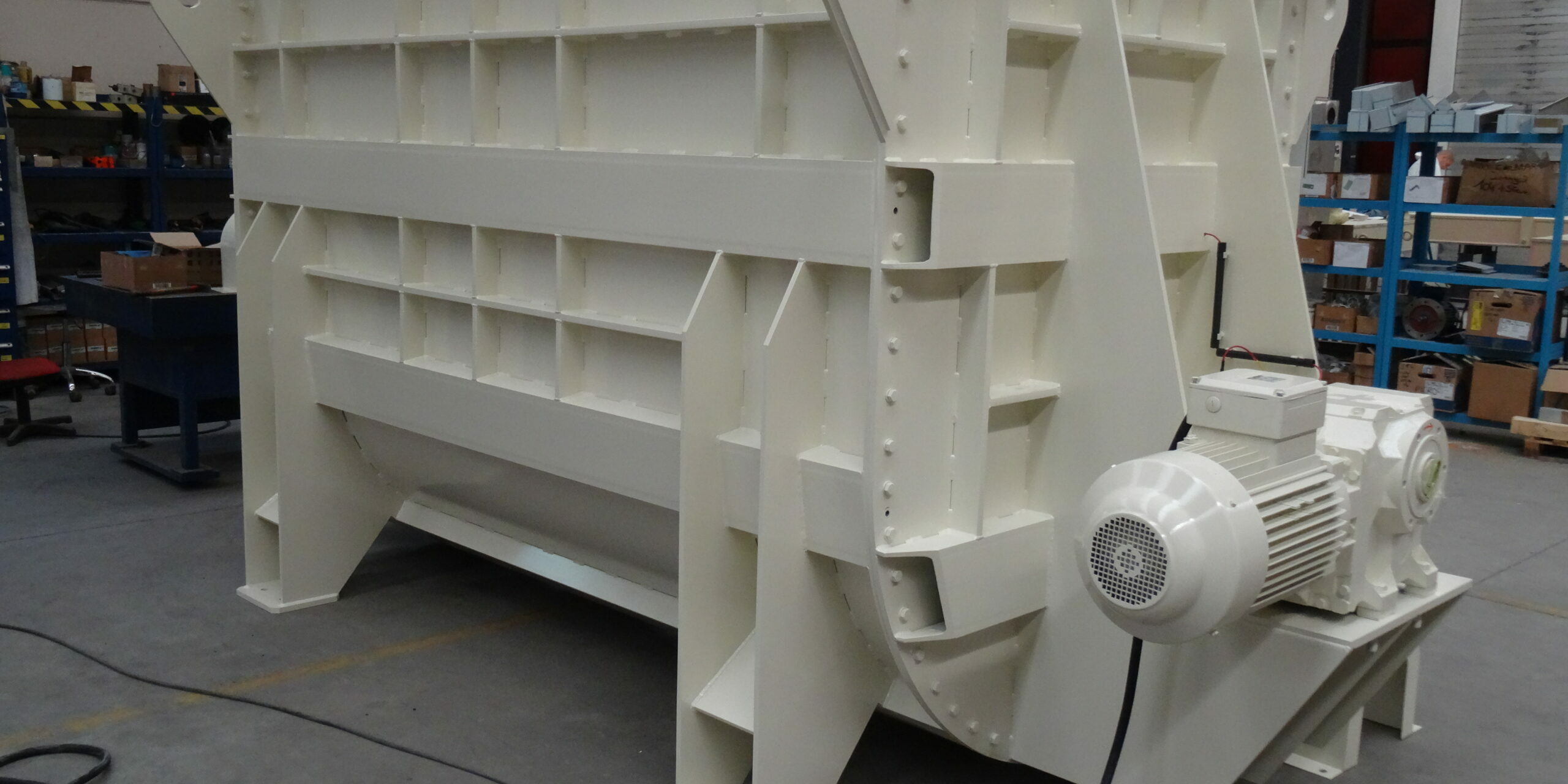

Blending solution for delicate materials

Lessine’s ribbon blenders provide the ideal solution for mixing and homogenizing materials in either continuous or batch processes, without altering or damaging the product’s properties.

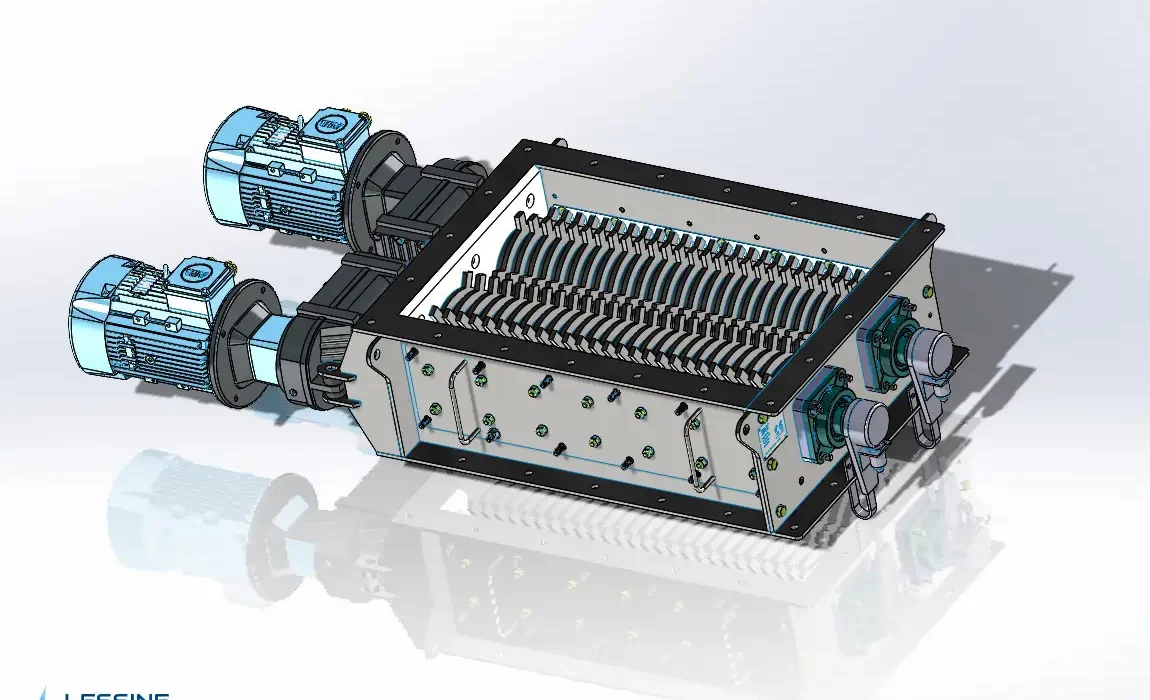

Operating principle

Ribbon blenders also known as horizontal ribbon blender or ribbon mixer use helical ribbons rotor (single, double, or triple action) that forces the different layers of product to mix thoroughly. Depending on the application, the discharge port can be central, total, or at the end, allowing for efficient and complete product discharge.

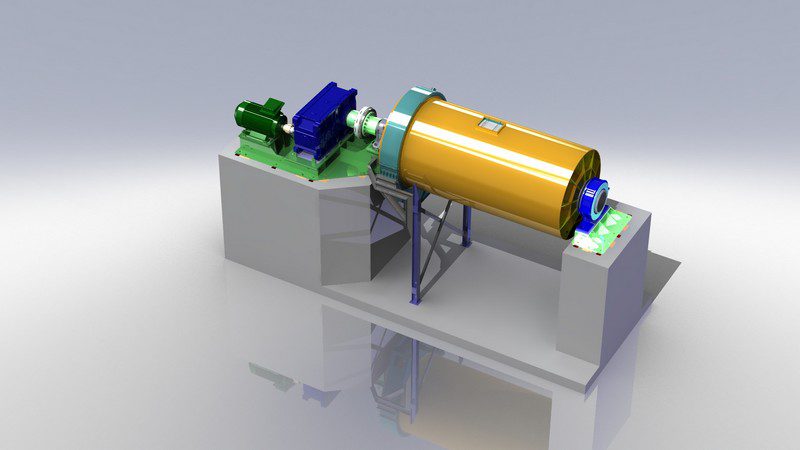

Applications of ribbon blender (horizontal ribbon blender, ribbon mixer)

The ribbon blender is versatile for homogenizing dry, wet, semi-liquid, and paste materials in the following industries:

- Circular economy and recycling

- Minerals and ores

- Fertilizers, chemicals, fine chemicals

- Food and pharmaceuticals

Advantages

- Gentle handling of the material

- Preservation of product properties

- Liquid impregnation possible

- Complete discharge from the blender

- Available for continuous or batch processes

- Option for heating or cooling the material

- Low energy consumption