What is it?

- Sturdy & flexible solution for percussion, friction and attrition crushing,

- The final product fineness can be adjusted to application requirements,

- Large range of flow rates.

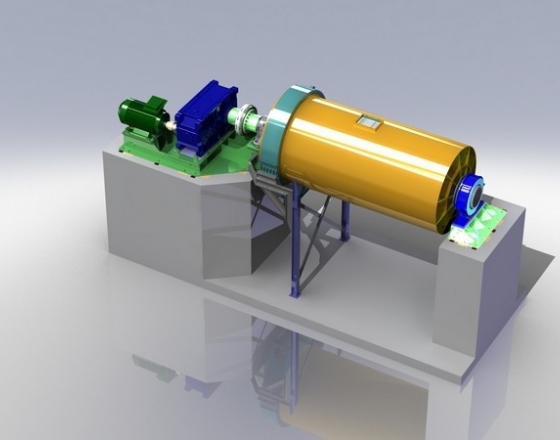

The ball mill (batch or continuous process) tends to be the most suitable solution for a wide range of applications

Working principle

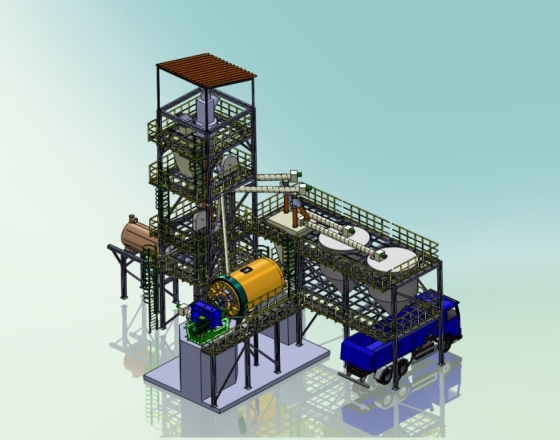

Environment and recycling Process

- The ball mill is made of a cylinder rotating on a horizontal shaft, including a grinding charge & fed with the (wet or dry) material to be finely ground,

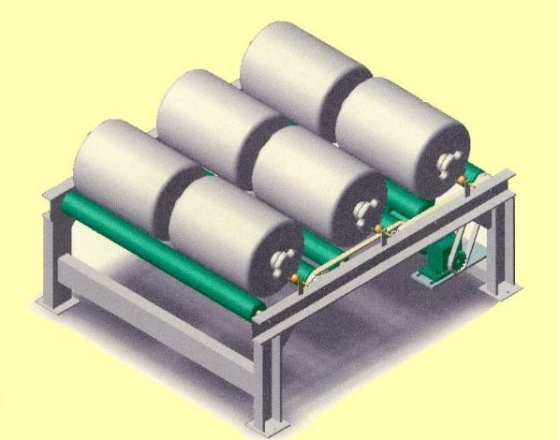

- +/- 2/3 of the drum volume is filled with the grinding charge,

- The drum rotates on the shaft at a precise rotation speed, optimized for crushing,

- The product is ground by impact, friction or attrition.

Features

- Continuous process (wet or dry product),

- From medium to large flow rates,

- Designed for overflow or peripheral unloading,

- Can be ventilated for drying or cooling,

- Drying is possible during grinding process or at crusher outlet,

- At outlet, the product undergoes a particle size separation (by screening, by air separator (most common) or by hydrocycloning (wet way)) to obtain desired paticle size. The oversize is recirculated in the crusher,

- Low maintenance costs,

- High reliability.

Application

Widely used in all sectors of industry:

- Fine milling of Minerals, metal products, chemical powders, agro-food & pharmaceutical (organic & inorganic) powders.

- For products from recycling and waste conversion

- Batch process or continuous process. For wet or dry products.

Benefits

- Sturdy & flexible solution,

- Wide range of products,

- Large variety of applications,

- Particle size from a few cm to 1 µm,

- Wet or dry ginding,

- Batch or continuous milling,

- Solutions fitting customer's needs,

- Many options available:

- Temparature maintenance,

- Drying,

- Products maintenance in a controlled-atmosphere,

- Sieve, aeraulic separation or hydrocycloning,

- Safety grid,

- Electrical cabinet,

- Sound-proofing,

- Adjustable particle size and particle size distribution,

- Minimum maintenance,

- Various sizes for different grinding finenesses and flow rates.