What is it?

The lab ball mill is a particularly suitable solution for grinding small quantities of products.

Working principle

Our lab ball mill is designed for grinding and homogenising a wide range of materials . This versatile equipment can fit a large variety of applications.

Process

The ball mill is made of cylinders rotating on a horizontal shaft. They are filled with a grinding charge and fed with the material to be ground.

The product is ground by impact, friction or attrition thanks to a precise rotation speed (optimised for grinding).

Features

Continuous working,

Wet or dry material,

For small quantities,

Limited investment,

Minimum floor space,

Low maintenance costs,

Versatility,

High reliability.

Range

Swivel roller jar mill

- Suitable for lab tests that have to be processed on a machine representing industrial ball milling,

- Jars from 7 to 10l capacity can be used to prepare 1 to 3l of material per batch,

- Thanks to its original ergonomics, it is a sturdy & easy-to-use equipment,

- Equipped with an electronic speed controller.

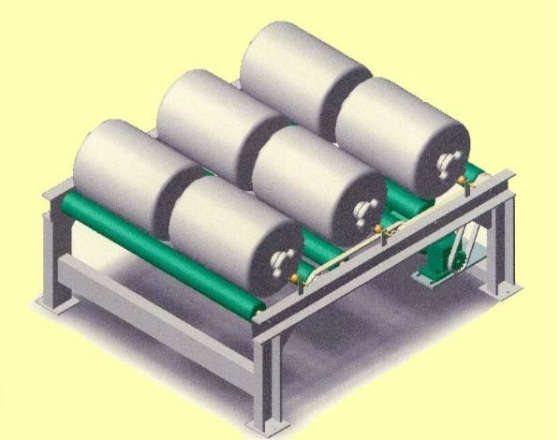

Roller jar mill for multiple jars

- Various designs depending on jars geometry & volume (up to 15l capacity),

- 1, 2 or 3 levels,

- Industrial grade,

- Intended for the production of several batches simultaneously,

- With a gearmotor equipped with frequency converter.

Roller drum mixer

- Intended for the production of a few dozens of kg, of small quantities or for large-scale tests,

- Industrial grade,

- Designed to work 24h a day,

- Jars or containers up to +/- 450mm diameter can be used,

- With a gearmotor equipped with frequency converter,

- Peripheral safety grid.

Applications

Widely used in all sectors of industry:

- Fine milling of Minerals, metal products, chemical powders, agro-food & pharmaceutical (organic & inorganic) powders.

- For products from recycling and waste conversion

- Batch or continuous process. For wet or dry products.

Benefits

- Sturdy & flexible solution,

- For small quantities,

- Wide range of products,

- Large variety of applications,

- Fine particle size,

- Wet or dry ginding,

- Solution fitting customer's needs,

- Adjustable particle size and particle size distribution,

- Minimum maintenance,

- Minimum floor space